Home > Products > Auto Painting Equipment > Auto Baking Oven / Painting Booth with IR Heating System

Auto Baking Oven / Painting Booth with IR Heating System

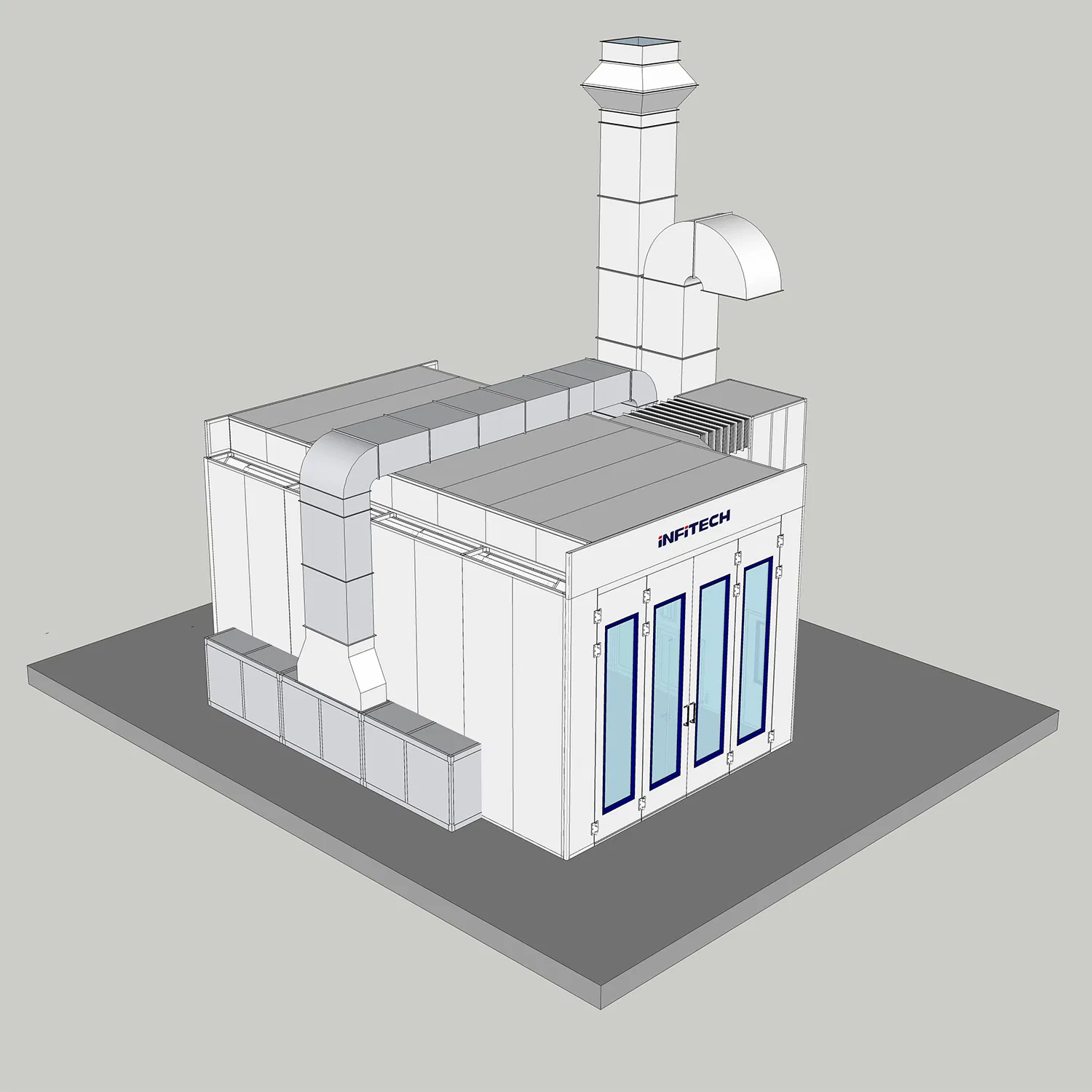

Auto baking oven / painting booth with IR heating system Basic informationSTANDARD DESIGNBS EN 13355: 2004 + A1: 2009BS EN 60204: 2006 + A1: 2009BOOTH DIMENSIONS Internal dimensions7000 X 4000 X 2800mm (L X WX H)External dimensions7110 X 5560 X 3810mm (L X W X H)BASEMENT Base designGalvanized sheet ......

Send Inquiry

Product Description

Auto baking oven / painting booth with IR heating system

Basic information

| STANDARD DESIGN | BS EN 13355: 2004 + A1: 2009 BS EN 60204: 2006 + A1: 2009 |

| BOOTH DIMENSIONS | |

| Internal dimensions | 7000 X 4000 X 2800mm (L X WX H) |

| External dimensions | 7110 X 5560 X 3810mm (L X W X H) |

| BASEMENT | |

| Base design | Galvanized sheet bending forming, full grids Basement(H): 350mm and can be adjustable |

| Carrying capacity of the grids | 650 kg/wheel |

| Filter area | 28m2 |

| Drive-in-ramps | optional |

| Grid description | Size: 997X756mm, 40X3mm, pressed steel grating grille instead of traditional twisted steel for the rail steel grating. Aesthetics, durability, stress resistance are the most important features of such steel grating. |

| CABIN | |

| Cabin structure | Vertical wall insert |

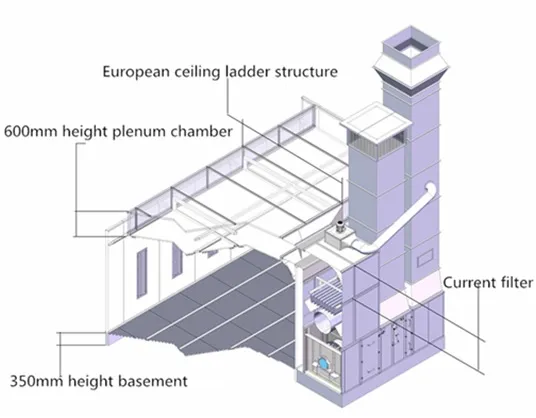

| Plenum height | 600mm |

| WALL PANEL | |

| Wall panel | 50mm wall panel, wallboard filler material: heat-resistant rock wool panel |

| Top panel | 50mm wall panel, wallboard filler material: heat-resistant rock wool panel |

| Edge material | 1.2mm galvanized steel plate bending forming |

| ENTRANCE DOOR | |

| Form | Manual door, 2 + 1 structure |

| Size | 3200 X 2700mm (W X H) |

| Arrangement and quantity | 1 set |

| Door description | Containing frame, with safety glass observation window |

| PERSONNEL DOOR | |

| Form | Frame structure |

| Size | 800 X 2000 mm (W×H) |

| Quantity | 1 set |

| Door description | With safety glass observation window |

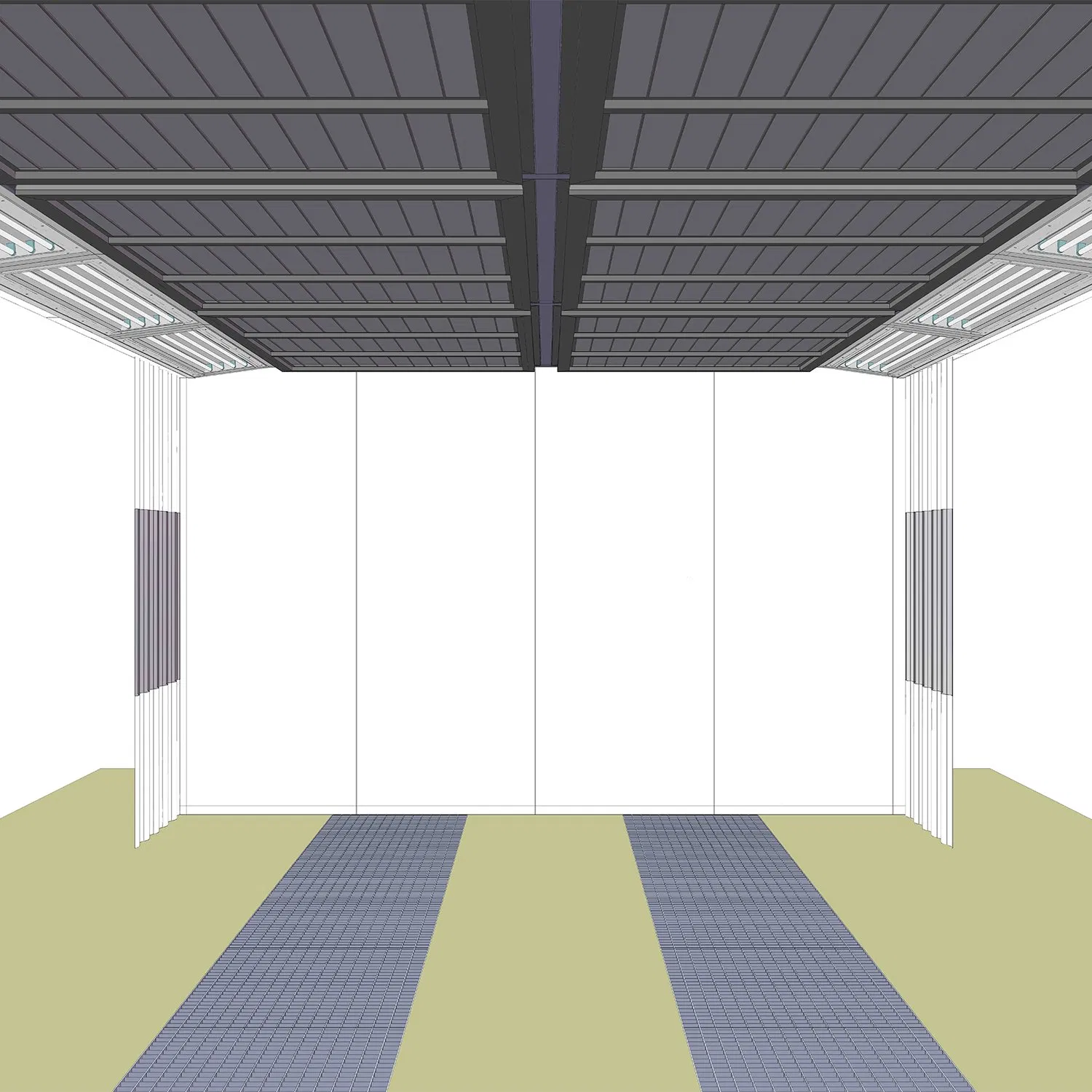

| CEILING LIGHTING | (LED lamp) |

| Quantity and power | 10 sets of light fixtures, each 6 X 18W, 1080W total |

| Lighting arrangement | On both sides |

| Lighting description | Protection grade IP55 |

| Brightness | > 900Lux |

| FILTRATION SYSTEM | |

| Pre-filter | EU3 grade pre-filter pocket filter |

| Ceiling filter | F5 class filter cotton, Model SP-600G |

| Bottom paint mist-collection | Fiberglass paint-resistance filters |

| Exhaust filter | Simple activated carbon filter mat, M type |

| INLET SYSTEM | |

| Inlet fan | Direct-type turbine fan |

| Power and motor description | 7.5KW, 970rpm, 380V, 50Hz, SIEMENS |

| Parameter of inlet fan | 28,000m3/h, 650pa |

| EXHAUST SYSTEM | |

| Exhaust fan | Direct-type turbine fan |

| Power and motor description | 7.5KW, 970rpm, 380V, 50Hz, SIEMENS |

| Parameter of exhaust fan | 28,000m3/h, 650pa |

| Empty loaded air speed | +/- 0.28m/s |

| NOISE | <78db |

| INFRARED RAY HEATING SYSTEM | |

| Drying form | Infrared ray |

| Power | 10 units,3X1kW/unit,total 30kW |

| Arrangement | 2 x 4 sets on both sides, 2 sets at the rear wall |

| PIPELINE CONFIGURATION | |

| Straight | 4 pieces |

| 90°elbow | 1 piece |

| 45°elbow | 1 piece |

| Rain hat | 1 piece |

| Reducer | 2 pieces |

| MANUAL DAMPER | 1 piece |

| ELECTRIC DAMPER | 1 piece |

| CONTROL SYSTEM | |

| Implementation standards | Standard Y/Δ step-down start control system |

| PLC programmable logic controller | PLC control, higher reliability, lower failure rate |

| Pressure detection | Pressure gauge indicates pressure inside the booth. |

| Features | Painting, levelling, baking, emergency stop switch, failure indication, over-temperature alarm indication, baking delay stop protection |

| SPECIAL ITEM | Rated power:18KW |

Detailed information

- Entrance door

Door size: 3200X2700(BXH) observation window size: 1995X500(BXH)

- Cabin structure

After the air flow goes through the heat exchanger rapidly, it will then pass through the diffuser, which provides important assistance to form the balanced and stable air distribution in the plenum.

The balanced airflow formed around the vehicle is achieved by the 350mm height basement. There is reasonable and effective diversion device for the basement, which helps to balance the airflow from end to end.

- Rock Wool Board

- Top plates: Double insulation board filled with 80KG/m³ rock wool, total thickness: 50mm, substrate thickness: 0.426mm

The panels are made of double galvanized steel plate with complementary treatment of five coats of paint (polyester, acrylic and silicone polyester heat-hardened with plastic film for added protection) on each side.

- Lighting system

- IP55 protection grade, light fixtures fully meet EU standards.

- Basement

- Plug-in type grid structure, full grids, safe and reliable

- Fiber-glass paint-stop filter (laid under the grids), G2 grade, paint holding capacity: 3.5KG/m2

- Airflow system

- Motor and fan are completely separated, which is compulsory requirement for fans in EN13355-2004.

- Adopting cylinder-drive paint-bake conversion damper, more quickly and accurately.

| Inlet / Exhaust motor | Inlet / Exhaust fan | Air volume | Drying system |

| 7.5KW SIEMENS | IT750 backward centrifugal fan, direct linkage | 28,000m³/h | IR heating system 30KW |

- Filtration system

| Item | Specification |

| Inlet filter | Pocket filter |

| Micro-dust filter | High efficiency SP-600G |

| Floor filter | Fiberglass filter |

| Exhaust filter | Activated carbon filter mat, M type |

- Control system

- Painting

- Warm painting

- Baking

- Lighting

- Emergency stop switch

- Failure stop switch

- Failure indication

- Dual-channel over-temperature protection

- PLC intelligent control

- Electric pressure balancing system

- Self-diagnostic fault

Main optional components: SIEMENS, OMRON, etc.- Warm painting

- Baking

- Lighting

- Emergency stop switch

- Failure stop switch

- Failure indication

- Dual-channel over-temperature protection

- PLC intelligent control

- Electric pressure balancing system

- Self-diagnostic fault

Infrared ray heating system

1) Infrared ray lamps

- Total 10 units of IR heating boxes (4 units on the left, 4 units on the right, 2 units on the back)

- Power: 3 x 1kW/unit, size: 585 x 80 x 500MM per set

- Each light box has 3pcs X 21 inches shortwave infrared lamps.

- The service time of the lamps can last as long as 5000 hours.

- Each box has a door, which keeps lamps off paint in painting phase. When it is in baking phase, the doors are opened.

- The lamps cannot work when doors are closed, which is achieved by 2 protective sensors set on the doors.

Microcomputer control system, touch button for the panel, stable and convenient to use.

3) Temperature control

When it reaches the setting temperature the heating system stops working automatically; when the temperature falls down below the setting temperature, the heating system starts working automatically.

4) Time control

The baking time can be set in advance. When the setting time is up, the heating system stops working automatically.

5) Group control

Total power is 30KW, controlled in 10 groups, 3KW per group. One group works individually or 10 groups work all together.

6) Power adjustment

The control box is installed with silicon controlled rectifier, which can adjust the heating power. When electricity power is not enough or no need to increase the temperature quickly, the operating power of the lamps can be turned down (10KW - 30KW).

7) Automatic slow start function

When the heating system is working, the silicon controlled rectifier is triggered slowly by the interior trigger of the temperature control system, which makes the infrared ray heating lamp work slowly, lessening the impact on the power system.

Please feel free to contact us if any inquiries. Thank you.

Related Category

Send Inquiry

Please Feel free to give your inquiry in the form below. We will reply you in 24 hours.